Author: Alexander Abele, Strategic Product Manager VARTA Storage

EXCLUSIVE. In an increasingly energy-aware world, the most cost-effective type of battery is sought for each application. The answer so far has been lead in most cases. Developments and improvements over several decades have helped to keep lead-acid battery solutions in a strong position for many applications. On the other hand, lithium-ion technology is conquering the market. So are the days of the lead-acid battery numbered, and will lithium-ion technology come to dominate in all applications?

Designers who rely on renewable energy solutions for industrial and automated vehicles such as commercial vehicles, buses, ships, mobility aids, agricultural, construction and cleaning vehicles, and lifting platforms, usually go with lead-acid batteries. There are some good reasons for this: in Europe and North America, 99 percent of end-of-life lead-acid batteries are collected and recycled. They are reliable and robust, boast a 150-year track record of safety, and have a comparatively low cost of entry, and are therefore a competitive alternative to other battery technologies.

Occasionally referred to as the workhorse of the battery world, lead-acid batteries often have the best price-performance ratio on the market. To users looking for a proven solution, lead-acid batteries offer durability while providing the level of traction required for light to heavy-duty use of machinery and vehicles for transporting goods and people.

Lead-acid batteries come in many shapes and are optimised for low energy and water costs, high availability and longer service life in cyclic use. Sealed lead-acid batteries minimise the time required for water refilling, cleaning and inspection, making them effectively maintenance-free. Sealed lead-acid batteries that are fitted with special venting systems are an ideal alternative when battery maintenance is difficult, such as in road sweepers, boats, buses, motorhomes or wheelchair applications.

Operating costs become the winning argument

Currently, lithium-ion technology is the talk of the town and is establishing itself in more and more applications. In view of this popularity, one might come to the conclusion that the days of the lead-acid battery are numbered and that lithium-ion technology will dominate in all applications in the future. It is undisputed that lead has and will continue to have a cost advantage over lithium. This is holds true for a number of applications in which weight, size, operational reliability, long service life and replacement costs across the entire lifetime of the machine lead to a higher availability of the machine or vehicle. However, the total operating costs will, in some cases, push the choice towards lithium solutions. Operating costs will become the dominant argument as the technology flourishes and new business models emerge, such as “battery or energy as a service”. Consequently, a lithium solution will be preferred for an ever-increasing number of applications. However, where this is not the case, lead will still dominate, so lead-based batteries are predicted to have a successful future.

Other considerations also play a role in choosing the ideal battery chemistry for an application, such as cycle life, energy throughput, environment, ventilation and specific use cases. Lithium-ion batteries do not produce any hydrogen gases when being charged. So there are no concerns about ventilation requirements in warehouses, making them more suitable for use in food retailing and the pharmaceutical industries.

Lithium-ion batteries offer new possibilities

These properties render lithium-ion batteries ideal for powering similar vehicles and equipment as lead-acid batteries do as previously described, including industrial trucks, automated guided vehicles (AGVs), cleaning machines, electric boats, electric utility vehicles, wheelchairs, lifting platforms and hybrid vehicles. Where space, weight, performance or energy efficiency are critical, lithium can enable design engineers to update existing solutions to create innovative products that complement or expand their portfolio.

One noticeable disadvantage of lithium-ion batteries would be their complexity. Entry costs for a lithium technology solution can be prohibitively high, especially for smaller companies, since it is necessary to custom design the cell stack, the battery management system, the interface and the packaging. However, they are also usually more innovative when it comes to placing new and revolutionary ideas on the market. Moreover, they often succeed faster and with greater agility than some of their larger competitors.

Customised solutions are in demand

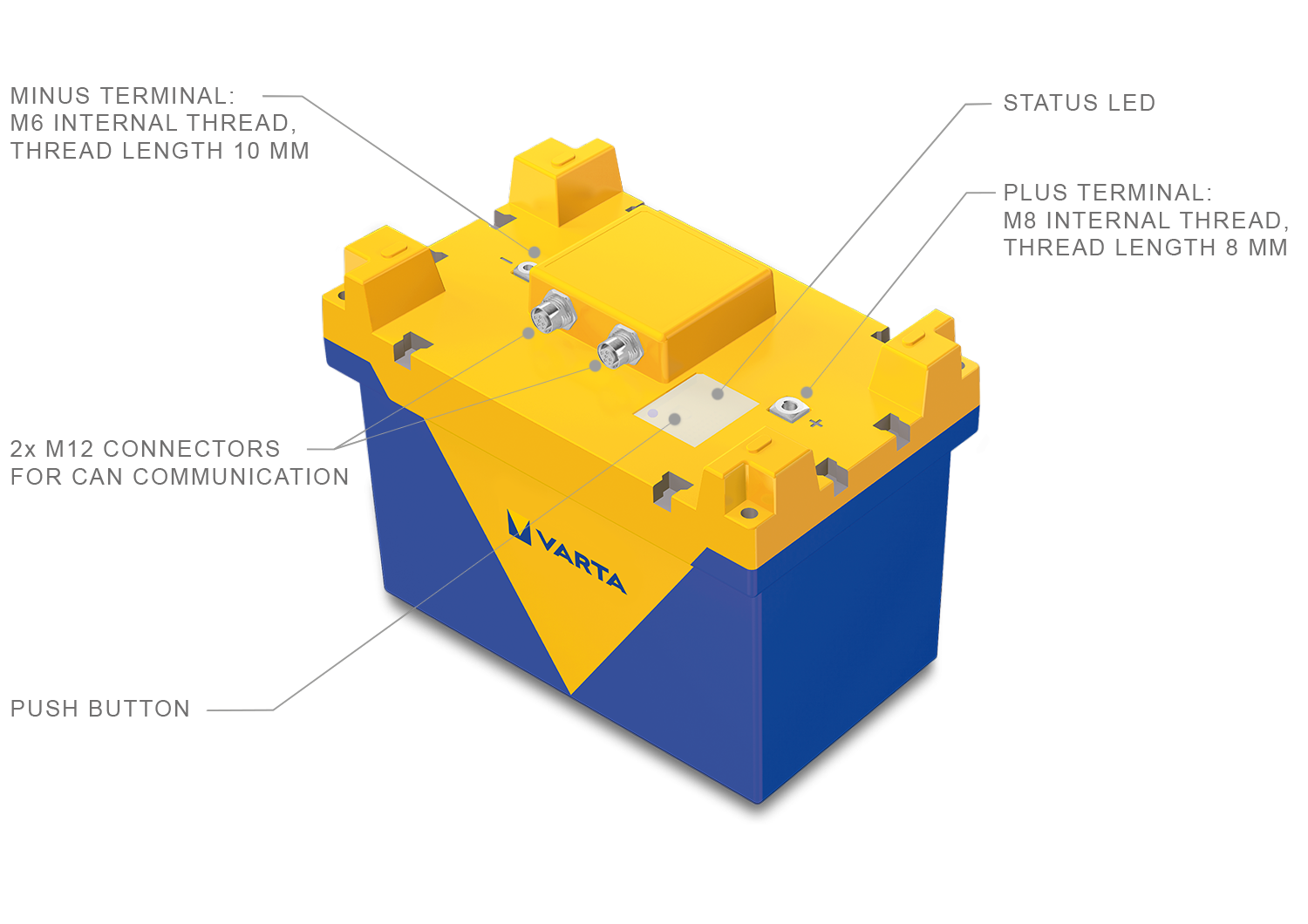

However, these companies usually have to invest most of their budget in developing the features and benefits that will help their product conquer the market as quickly as possible. This will generally leave only a narrow financial margin to develop a customised battery solution. Support is coming from the battery industry. VARTA, for example, has introduced a range of application-specific batteries (ASB) based on lithium-ion technology that can be used without upfront costs for development, NRE, NRT, certification and approval costs. This way, designing engineers can focus primarily on product development and deploy batteries into their application with minimal effort.

So are lead-acid and lithium-ion batteries going head-to-head? The answer today and in the future lies in a coexistence of the two. The days of the lead-acid battery are by no means numbered. They are well-established in certain applications and adapt to new challenges through technical innovations. On an equal footing are the more recent lithium-ion batteries with the recognisable advantage of being able to bring about individual customised solutions for new applications more easily and quickly. In the foreseeable future, therefore, both technologies will thrive side-by-side in serving their markets without undermining each other.